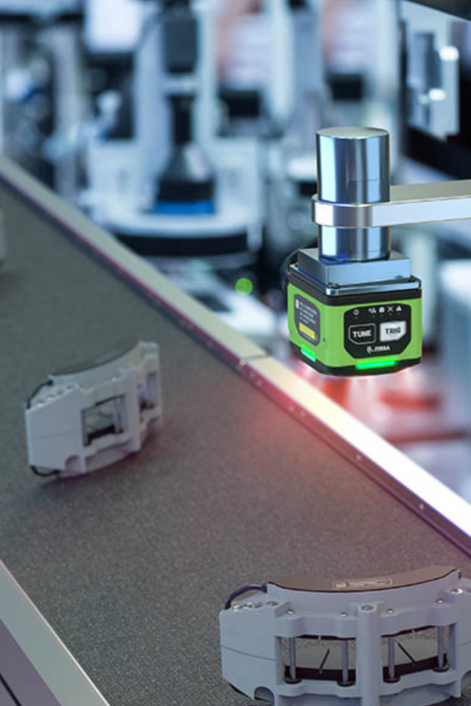

Fixed Industrial Scanners > GS20

The GS20 Connectivity Gateway for Scan Tunnel Applications Substantially Increases Package Tracking and Sorting Throughput

In today’s typical scan tunnel, all cameras capture barcodes, process the data and send the processed data to the host — and one camera is designated as the leader, also responsible for coordination and communications with the other cameras in the tunnel. With the GS20 as a designated leader module, all connected cameras become single purpose devices, doing only what they were designed to do best — capture barcodes. With support for up to 16 cameras, the GS20 aggregates all captured scan data to quickly send only the information required by the host application.

The result? Processing inefficiencies are eliminated, enabling all of the cameras in tunnels to achieve peak scanning capacity. And your customers achieve a maximum return on their scan tunnel investments.

- Supports an array of up to 16 cameras for configuration flexibility to support a variety of package sizes and label placements

- Data filtering capabilities eliminates duplicate code reads, extracting and consolidating only the appropriate data for the host application.

- Quick setup with Automatic GPIO mirroring, which captures the configuration settings of one scanner and mirrors the I/O settings to all other scanners.

- Mix and match camera models by connecting to virtually any TCP/IP-enabled Zebra device for complete configuration flexibility

- Easily integrate with existing production lines and systems to reduce deployment time and cost.

Benefits of the GS20

Supports up to 16 Scanners for Superior Coverage

Connects to more cameras than leading competitors for configuration flexibility to support a variety of package sizes and label orientations.

Intuitive Web-Based Setup — No Coding Required

The integrated web-based HMI graphical interface lets administrators click their way through configuration of all aspects of the GS20, including processing of barcode data from all scanners.

Easy Integration With Your Existing Production Lines and Systems

Built-in support for Rockwell, Siemens, Mitsubishi and Omron PLC devices simplifies integration, reducing deployment time and cost.

The primary markets/applications for the GS20 are:

- Automotive

- Food & Beverage

- Medical/Pharma

- Robotics

- Semiconductor and Electronics

- Transportation and Logistics

EASY TO SET UP

- Game-changing scan tunnel architecture

Since all barcode data is now sent to the GS20, cameras no longer need to process data, providing three key benefits: setup is simplified, cameras can now achieve maximum scanning speeds and conveyor speeds are increased, improving throughput. - Intuitive web-based setup — no coding required

The integrated web-based HMI graphical interface lets administrators click their way through configuration of all aspects of the GS20, including processing of barcode data from all cameras. - Rich data filtering capabilities

The GS20 eliminates duplicate barcodes and extracts the desired data for the host application through string filters — specify an exact match of an entire string, or a match at the beginning, end or anywhere in the string. - Supports up to 16 cameras for superior coverage

Connects to more cameras than leading competitors for configuration flexibility — supports a variety of package sizes, regardless of label positioning. - Configure GPIO for all cameras in record time

With Automatic GPIO mirroring, setting up trigger mode for up to 16 cameras is as easy as setting up one — all I/O settings are then mirrored to all other cameras. - Multiple triggering modes

Choose the scanning mode that best meets the needs of the application — single shot, level, continuous or presentation

EASY TO DEPLOY

- Easy integration with existing production lines and systems

Built-in support for Rockwell, Siemens, Mitsubishi and Omron PLC devices simplifies integration, reducing deployment time and cost. - Ultra-rugged and deployable practically anywhere

The aluminum housing is chemical and oil resistant. And with IP65 and IP67 sealing, the GS20 is dustproof and waterproof. - Mix and match models to meet any need

The GS20 can connect to virtually any TCP/IP-enabled device, providing complete configuration flexibility. Scan tunnels can be configured with different camera models, and even handheld scanners and third-party devices — a major competitive differentiator. - Flexible power options

Reduce setup complexity and cost with support for Power-over-Ethernet (PoE). This standard feature powers the GS20 and attached accessories right over the network, eliminating the cost of power drops and power supplies. And if you don’t have a PoE infrastructure, no problem. You can also power the GS20 with a standard 24V DC power supply. - Shared accessory ecosystem

The GS20 utilizes the same accessory family as Zebra’s Fixed Industrial Scanner family, simplifying purchasing, deployment and management.

EASY TO RUN

- Eliminates the need for a separate computer or additional software

Since all data processing is performed on the GS20, there’s no need to purchase and manage a desktop computer or additional software. - Easily monitor your entire scan tunnel with Heartbeat+

View live performance of the GS20 leader and all follower cameras in an easy-to-read single status page. And alerts notify users immediately if a camera is disconnected. - Future proof scan tunnels

No need to worry if the GS20 will be compatible with a newly installed next generation camera — the GS20 was designed to be compatible with most current and future Zebra fixed industrial scanners, as well as TCP/IP-enabled devices. - Complete support service — everything is covered

Get the constant peak performance and device uptime today’s businesses demand with Zebra OneCare™ Essential and Select Support Services. Unexpected disruptions and unbudgeted repair expenses are eliminated. Everything is covered — including normal wear and tear and accidental damage. Users can customize their support plan with numerous options to get the service level their business needs, including next-day delivery of a replacement device, on-site support, cloud-based visibility into their contracts, repair data, tech support cases — and more.

Help your customer protect their Zebra devices for constant peak performance with these recommended maintenance plans and signature services.

Zebra OneCare Maintenance Plans

Device uptime, confidence, and savings — that’s what you get with Zebra OneCare™ maintenance plans. Customers protect business-critical devices and eliminate disruptions and unplanned repair expenses. But they need more. Your customer needs visibility that gives them insight into all of their support activities.

Learn More

Global Services

- Professional Services

Adding innovative tech is critical to success, but it can be complex and disruptive. Professional Services help your customers accelerate adoption, and maximize productivity without affecting their workflows, business processes and finances.

Learn More

- VisibilityIQ Foresight

Zebra's VisibilityIQ Foresight is a cloud-based solution that aggregates data from MDM and other device data sources to provide your customer with the business intelligence they need to get the most out of their data investment.

Learn More

Zebra Aurora Focus Software

Zebra Aurora Focus brings a new level of elegance and simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this simple but powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Learn More

Martin Duguay

Business Development Manager - Canada

P: 1-800-317-2323 ex. 5501

E: mduguay@bluestarinc.com